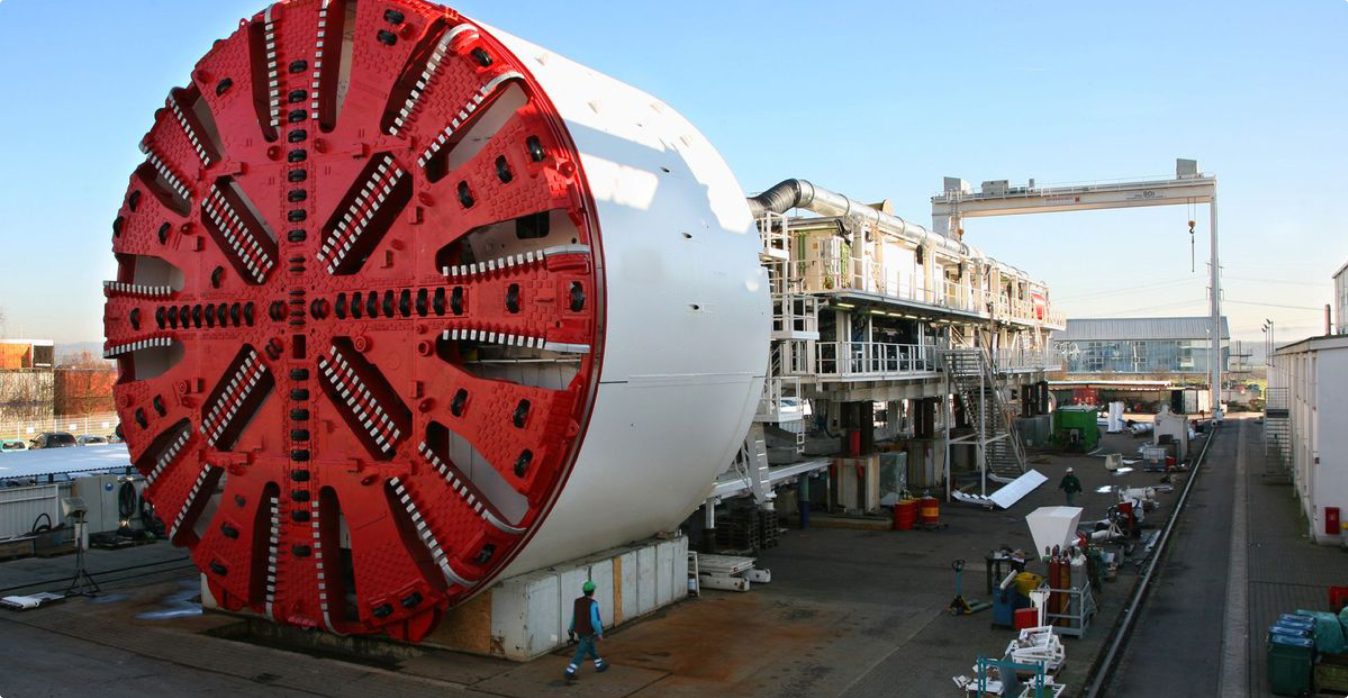

Hydraulic cylinders play a crucial role in shield tunneling machines and hard rock boring machines, controlling various movements and operations of these specialized equipment. In shield tunneling, hydraulic cylinders drive the rotation and advancement of the tunneling head while coordinating with the thrust system to ensure smooth progress. In hard rock boring, they control the rotation, feed, and mixing and transportation of rock fragments of the rock drill bit. These cylinders not only need to be reliable and durable but also provide high performance to tackle various challenges in underground engineering, ensuring efficient tunneling and rock excavation.

In shield tunneling machines, electric cylinders and pneumatic cylinders play key roles. Electric cylinders are used to adjust the cutterhead, control earth conveyance, and operate the brushing system, allowing the machine to adapt to different geological conditions and maintain tunnel quality. Pneumatic cylinders are employed in the thrust system, control of the turbofans, and lubrication of the cutterhead, driving the shield tunneling machine forward, ensuring ventilation, and prolonging equipment lifespan. These components are crucial for enhancing the efficiency, safety, and quality of tunnel construction, playing an indispensable role in urban infrastructure development.

In wet spraying machines, hydraulic cylinders and pneumatic cylinders play important roles. Hydraulic cylinders are used to control the elevation, extension, rotation, and pressure of the spraying arm, ensuring accurate concrete spraying and positioning. They can also be utilized to control the water supply system, ensuring the construction site remains damp. Pneumatic cylinders are used to adjust the operator's cabin, nozzles, and other components, providing the operator with better visibility and comfort, and ensuring uniform concrete coverage on the tunnel walls. These components are crucial for the success of tunnel reinforcement projects and construction quality, contributing to the improvement of tunnel structural integrity and safety.