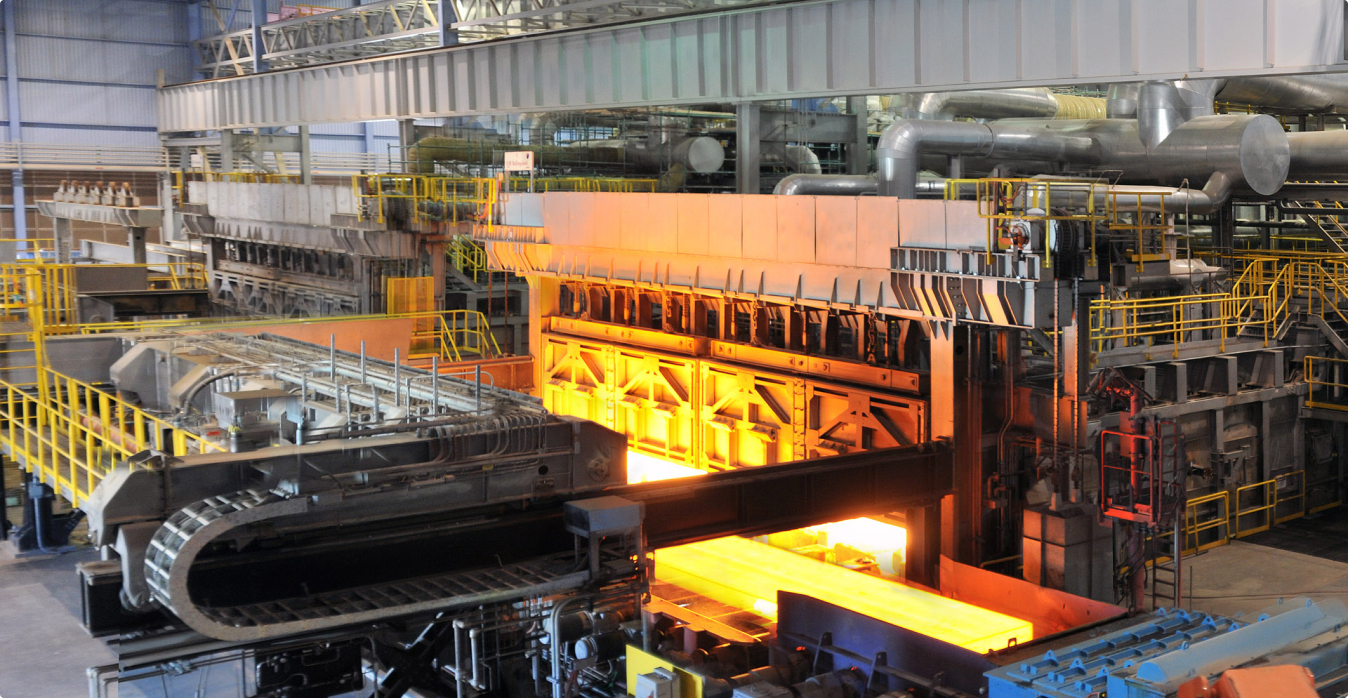

In the field of metallurgical die casting, hydraulic and pneumatic cylinders play crucial roles in controlling the force and motion during various metal casting processes. Here is the information related to the force and hydraulic/pneumatic cylinders in metallurgical die casting:

1.Clamping Force Control: The clamping force of a metallurgical die casting machine needs precise control during the mold closing phase to ensure proper casting formation. Hydraulic cylinders are commonly used to apply and maintain the required clamping force, ensuring the mold's seal and stability.

2.Injection Pressure Control: During the casting process, metal alloys need to be injected into the mold through a nozzle. Hydraulic and pneumatic cylinders are used to precisely control the injection pressure, ensuring even filling of the mold to prevent air pockets and defects.

3.Mold Opening and Closing: The mold of a metallurgical die casting machine must be able to open and close rapidly and precisely. This is often achieved through hydraulic or pneumatic cylinders, increasing production efficiency and mold lifespan.

4.Ejector Force and Ejection Mechanism: After the mold opens, force is applied to push the castings out of the mold. Hydraulic and pneumatic cylinders drive the ejection mechanisms, ensuring smooth removal of the castings.

5.Automation Control: Modern metallurgical die casting machines often employ automated control systems where hydraulic and pneumatic cylinders work in conjunction with sensors and controllers to achieve highly precise operations and monitoring.

6.Safety Systems: Safety is paramount in operating metallurgical die casting machines. Hydraulic and pneumatic cylinders are utilized in driving safety systems such as fixture locking, mold protection, and emergency stop functions, ensuring the safety of both the operators and the equipment.

Hydraulic and pneumatic cylinders in metallurgical die casting machines play crucial roles in controlling and adjusting various operations to ensure the manufacture of high-quality castings. They need to possess high precision, reliability, and rapid responsiveness to meet the demands of modern metallurgical die casting processes.

In the cement industry, cylinders, both pneumatic and hydraulic, are indispensable sources of power, providing critical support for production and processing processes. Pneumatic cylinders, through precise pneumatic control, manage mixing, conveying, gate control, packaging, and equipment maintenance, ensuring seamless operation of the processes. Hydraulic cylinders, on the other hand, play roles in high-pressure applications, adjustments, positioning, vibration, and screening, contributing to the efficient processing of cement production lines. They represent outstanding examples of automation and hydraulic technology, offering precision, reliability, and efficiency to the cement industry. Moreover, they are essential partners in the cement industry, ensuring raw materials are transformed into high-quality finished products. Choosing pneumatic and hydraulic cylinders means opting for excellent power and control, providing robust support for the thriving development of the cement industry.

In the sheet metal industry, cylinders, both pneumatic and hydraulic, are indispensable sources of power, providing support for various processing, forming, and assembly processes. Pneumatic cylinders precisely control machine tools, molds, material handling, and assembly, ensuring high precision and consistency. Hydraulic cylinders provide high pressure for deep drawing, bending, and hydraulic clamping, ensuring the precise shaping of sheet metal workpieces. They promote automation and efficient production, enhancing flexibility and reliability. Choosing pneumatic and hydraulic cylinders means opting for excellent performance and production efficiency, driving the prosperous development of the sheet metal industry.

In the solid waste crushing industry, pneumatic and hydraulic cylinders are indispensable sources of power, providing crucial support for the handling, crushing, and decomposition of waste materials. Pneumatic cylinders control feeding, discharging, tools, and equipment operations, ensuring efficient processing of waste materials. Hydraulic cylinders provide high pressure, adjustments, and positioning to ensure comprehensive crushing of waste and effective separation. They promote waste management, resource recycling, and environmental sustainability, reducing waste processing costs. Choosing the appropriate pneumatic and hydraulic cylinders helps solid waste crushing equipment achieve outstanding performance and efficiency, contributing to sustainable development and resource reuse.